As the story goes, we’re now in 2019, but if you’ve followed NCR for any length of time, you know the S13 is still not moving under its own power since it was parked up at the new property – but why?

As mentioned, we got stuck into some home improvement and adjusting to a rural lifestyle. That meant a lot of time and money was being spent on new tools, new skills, and increasingly more challenging and time-consuming projects. Then I changed jobs after a decade, then went through a few daily drivers trying to find something that ticked all the boxes and finally in August hat year got back to the Silvia and sent the engine bits to workshop in Sydney.

I told the owner “no rush” the car has a lot of work to do before it’s ready for the new engine, but keep chipping away between other things and as I get closer to being ready, I’ll keep you posted so you know to ramp up/finish off.

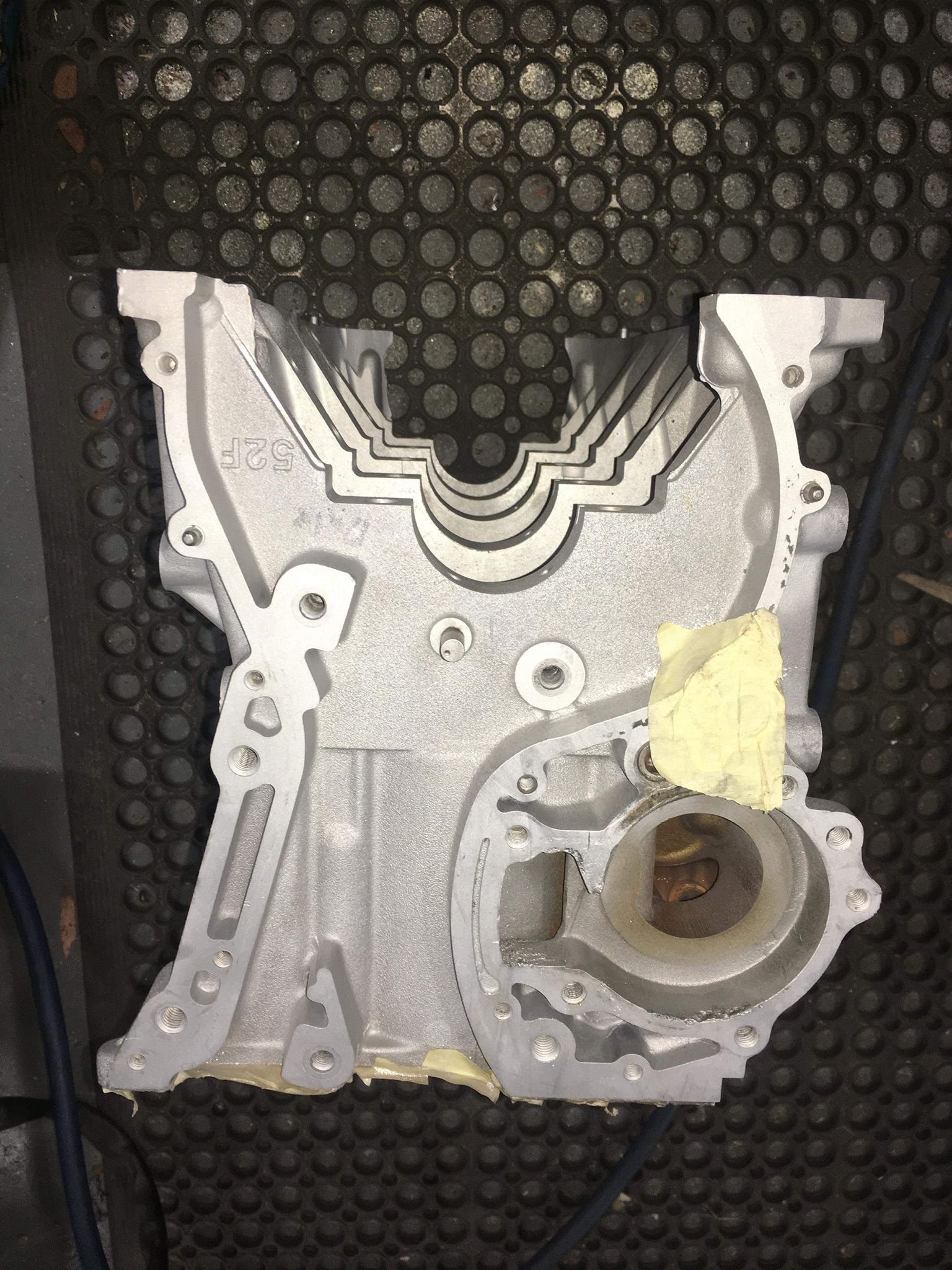

After issues with freight and some initial delays, it wasn’t until Feb 2020 when the build actually kicked off as he advised the;

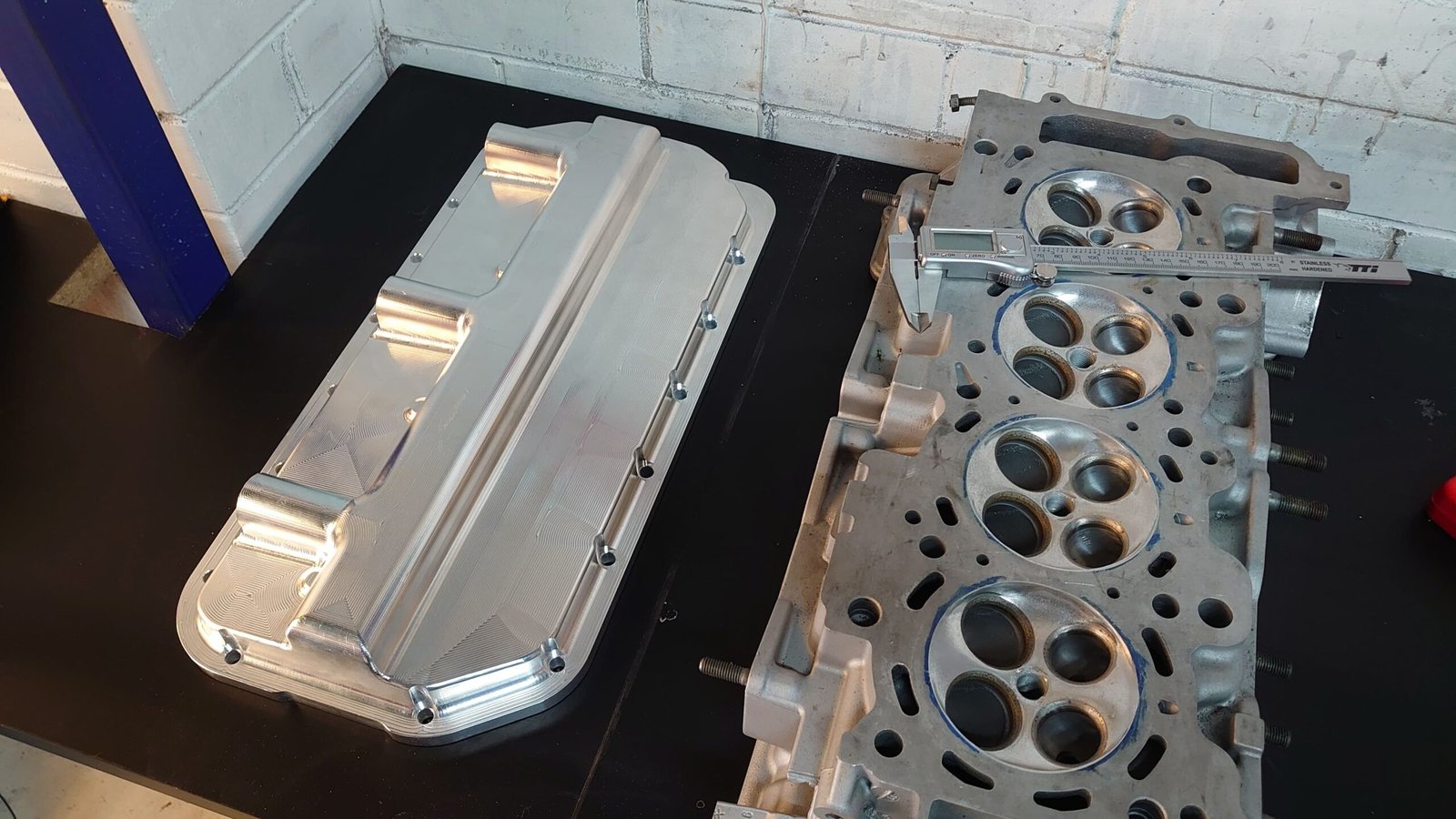

– Head has been inspected/stripped and cleaned.

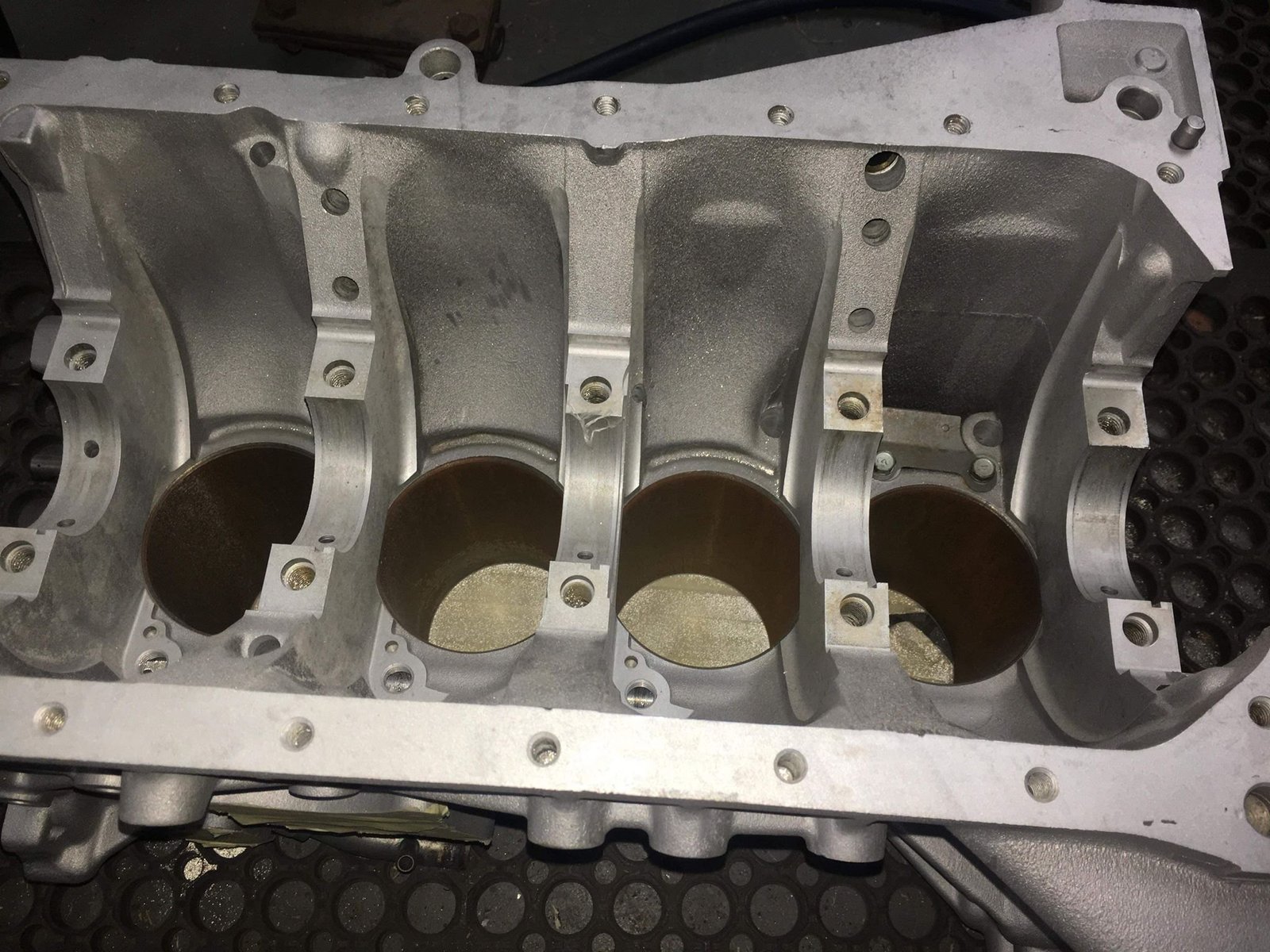

– Block has been inspected, squared, and is being measured for clearances. Soon to be CNC’d then bead blasted.

– Crank has been crack tested and journals all checked A-OK.

Awesome, I thought, we’ll have an engine soon enough and as I was still busy modding the daily and doing more house projects a bit of a delay was no big deal.

Fast forward to August and we start to see some pics trickling in, progress is slow, but something is better than nothing.

November rolls around, not much is happening on the engine building front, a bit more head work has progressed and when asked, the workshop owner is often busy with other things, his race car(s), relationship/business issues etc, other customer work etc. I’m not too fussed at this stage as I’ve had my hands full also.

I feel guilty so go and give the Silvia a run on stands and decide it’s probably time to build that bigger shed I’d talked about and start prepping the car for the engine.

By Feb 2021 the new 14×10 shed is standing, floor sealed, apron poured, and is ready for wiring, a hoist, and to move all my junk in. In April we get a few more minor updates from the workshop, he’s working on the head. In May we make a progress payment for various works done, he tells me he’s “on the home straight” I start thinking about roll cages.

June comes around and the shed wiring is now done, hoist is installed, and most of my stuff has been moved in – I even find time to buy and restore a nice Coonara for the cold Victorian months.

The Silvia finally makes its maiden voyage on the hoist which marks the official launch of No Crust Racing, I’d waited to have a hoist for a long time so this was a moment of personal satisfaction.

By November, the car is looking a little worse for wear as the old CA, gearbox, ECU, loom, Nistune, cage, and wheels have all been removed and shipped off to new owners as we make way for new bits to come. Decision is made not to hack up the fairly good condition dash etc so it’s pulled and sold – an R34 Dash top half is acquired cheap to mod and install after the cage is done.

5 Stud hubs and new 350z Brembos have been purchased and work commences on fitting those using a GKtech weld on caliper adaptor (rear only) this will test my fledgling welding skills! A spare SR20 block, crank, and a nice alloy radiator pops up for the right price so I snap that up and pop it on the shelf. The block gets inspected and it’s a virgin bore, but it’s got a few damaged threads and dowel pin receivers – the crank tests perfectly and gets wrapped up and stored.

Feb 22, The caliper adaptor job is completed, it took 2 goes to get it right, but the end result looks decent. I took the opportunity to press in new bushes to the hubs, bought some HFM 2 piece rotors for the front, DBAs for the rear and some Intima pads all around, the RR doesn’t exist at this point and the RS is as good as it gets.

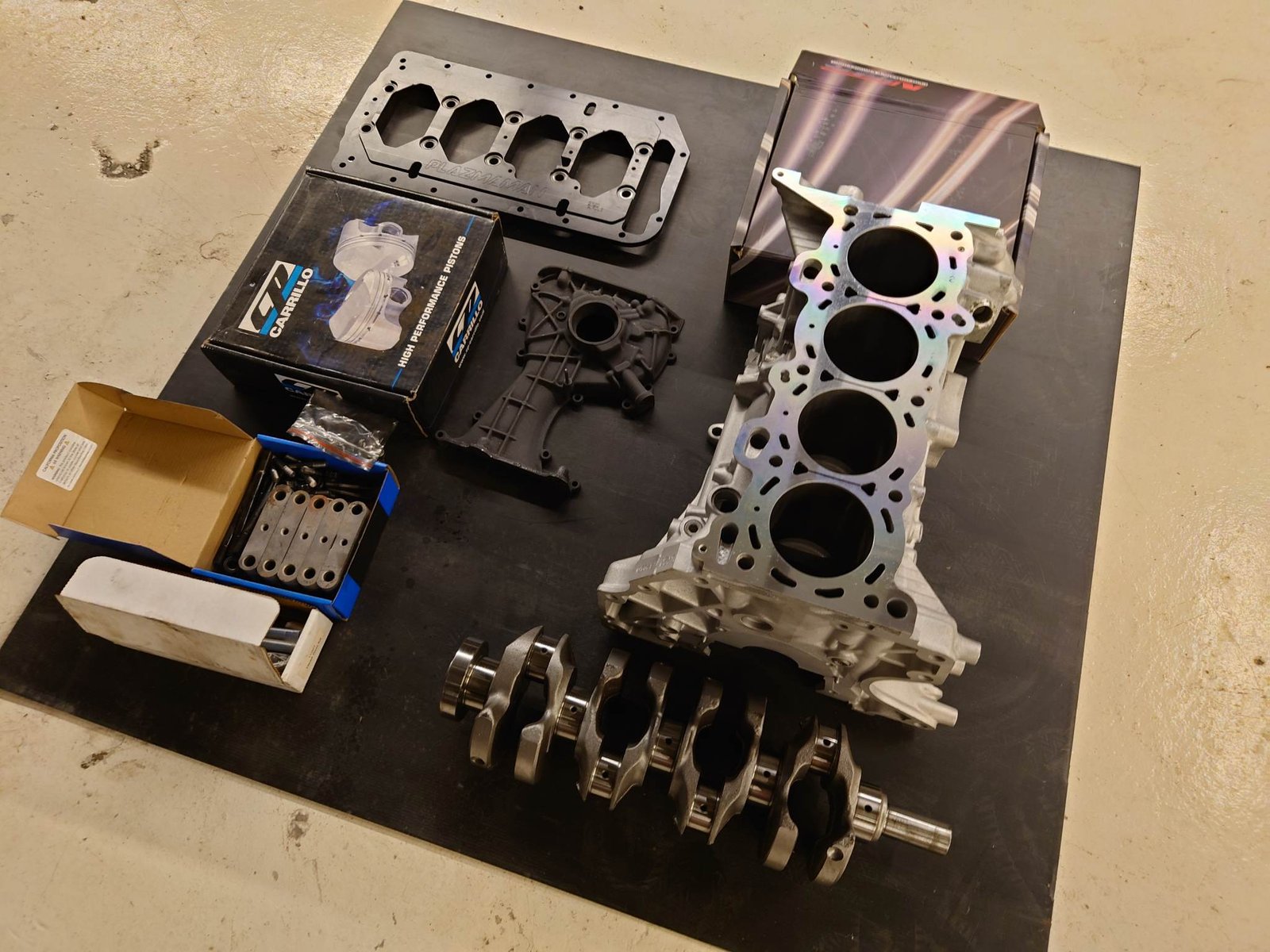

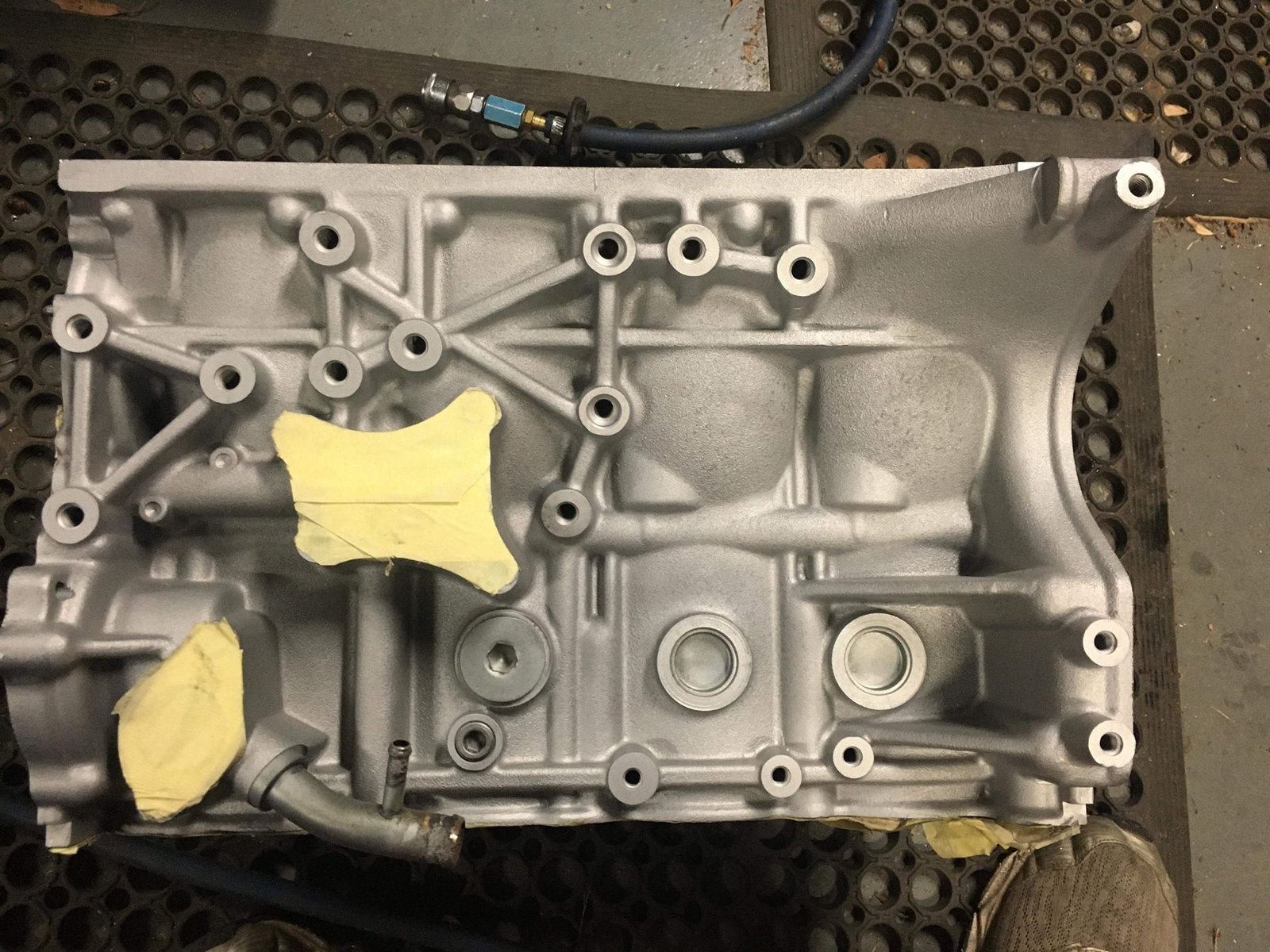

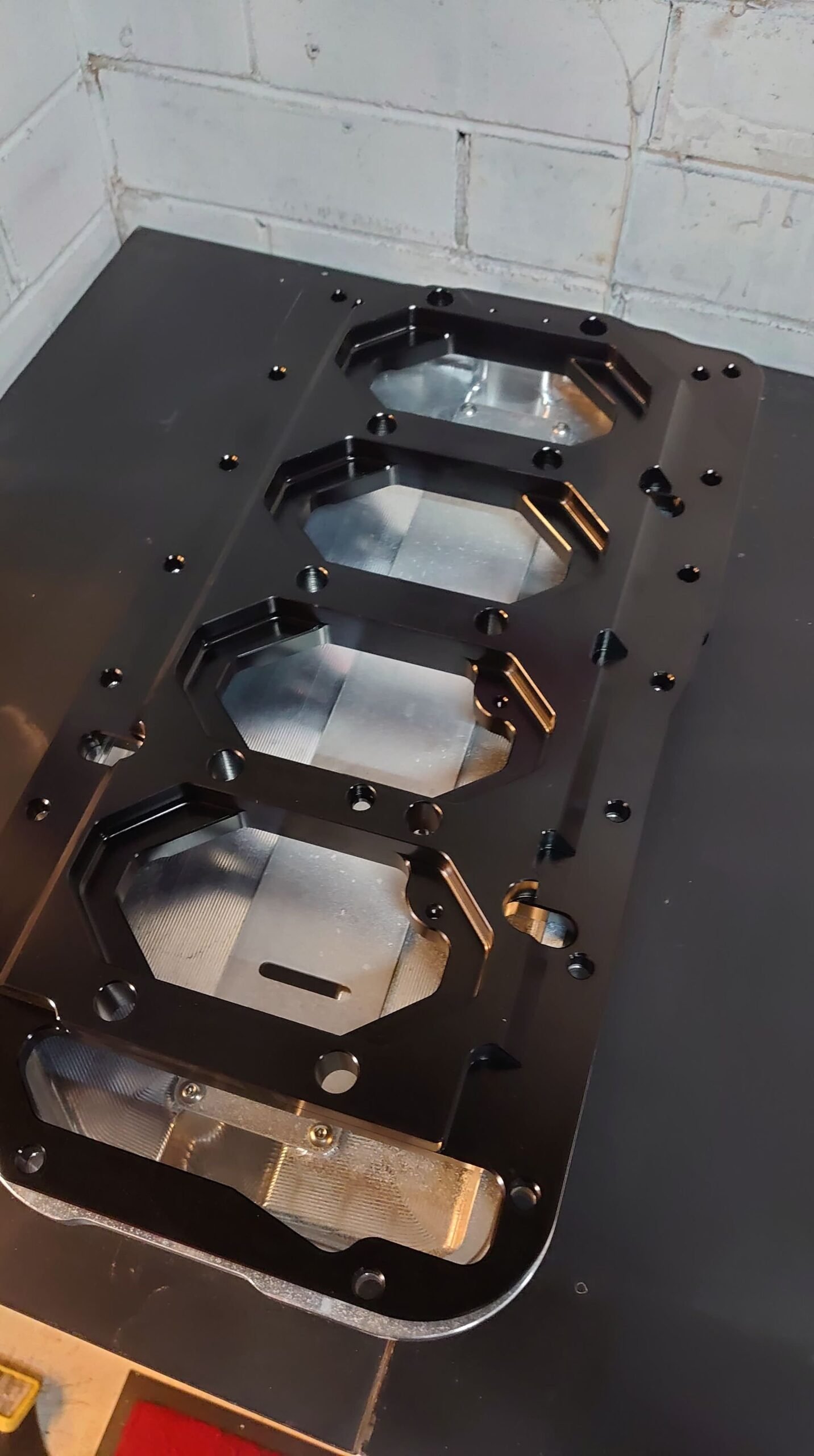

A Mazworx billet pan comes up at a very good price so the call is made to go dry sump on the SR as work slowly continues in the background. The workshop is very happy with the quality of the pan, but notes the Plazmaman billet girdle is not exact and needs to be machined.

A friend loans me some 18×10 wheels so I can assess fitment, clearance is an issue, more camber will help and tubs are looking like a necessary requirement – orders are made.

It’s August now, we see some pics of the girdle being test fitted with some custom studs I’ve had made up as requested, the block sent, despite being a virgin bore, doesn’t test up well on the Ultrasonic and is swapped out for something thicker. He’s busy on the head, which has been CNC’d and CC’d, and we start to see some pics of the porting work.

Progress on the car itself has slowed as I’ve been busy bringing an old Farm Ute up to useful status and modding the daily for van towing duties after we decide no more tents and pickup a little 16ft pop top.

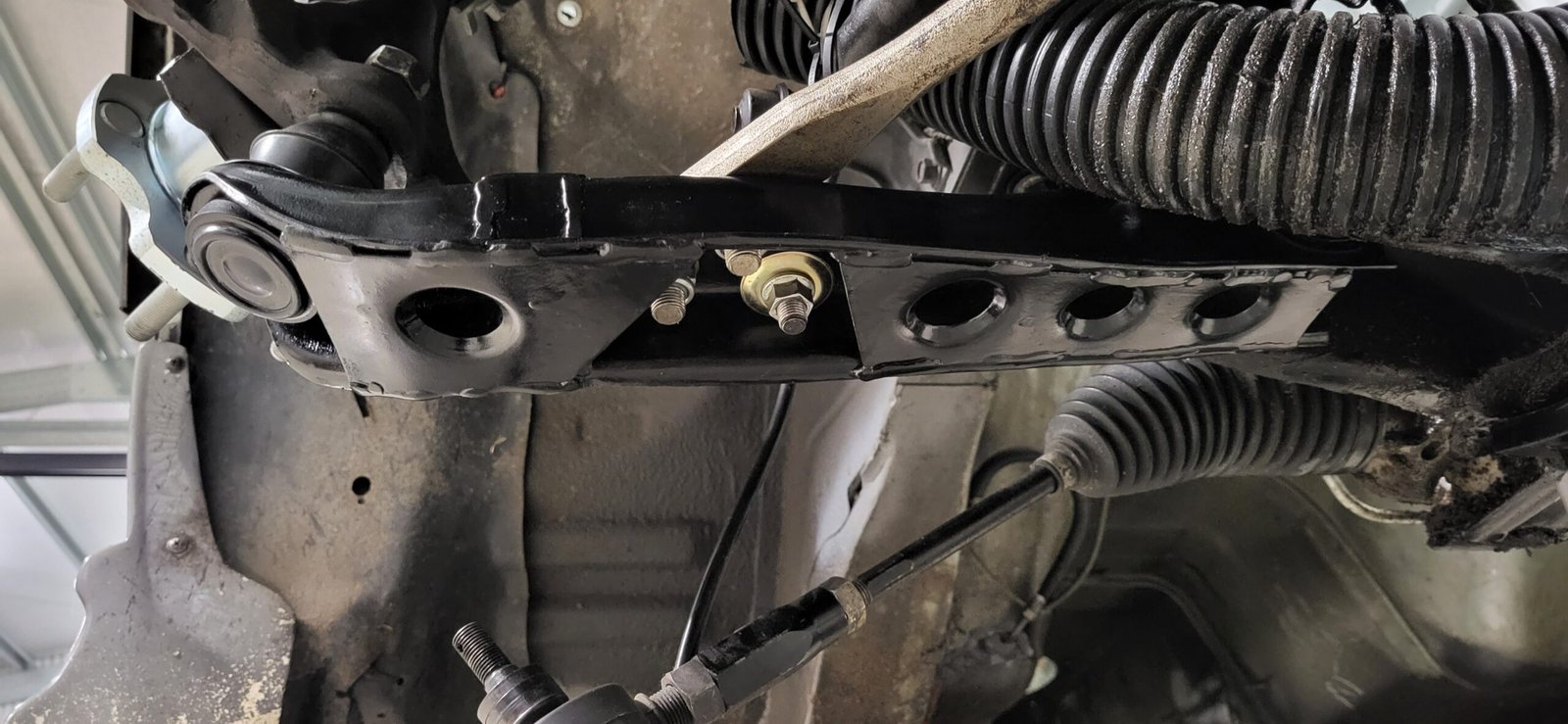

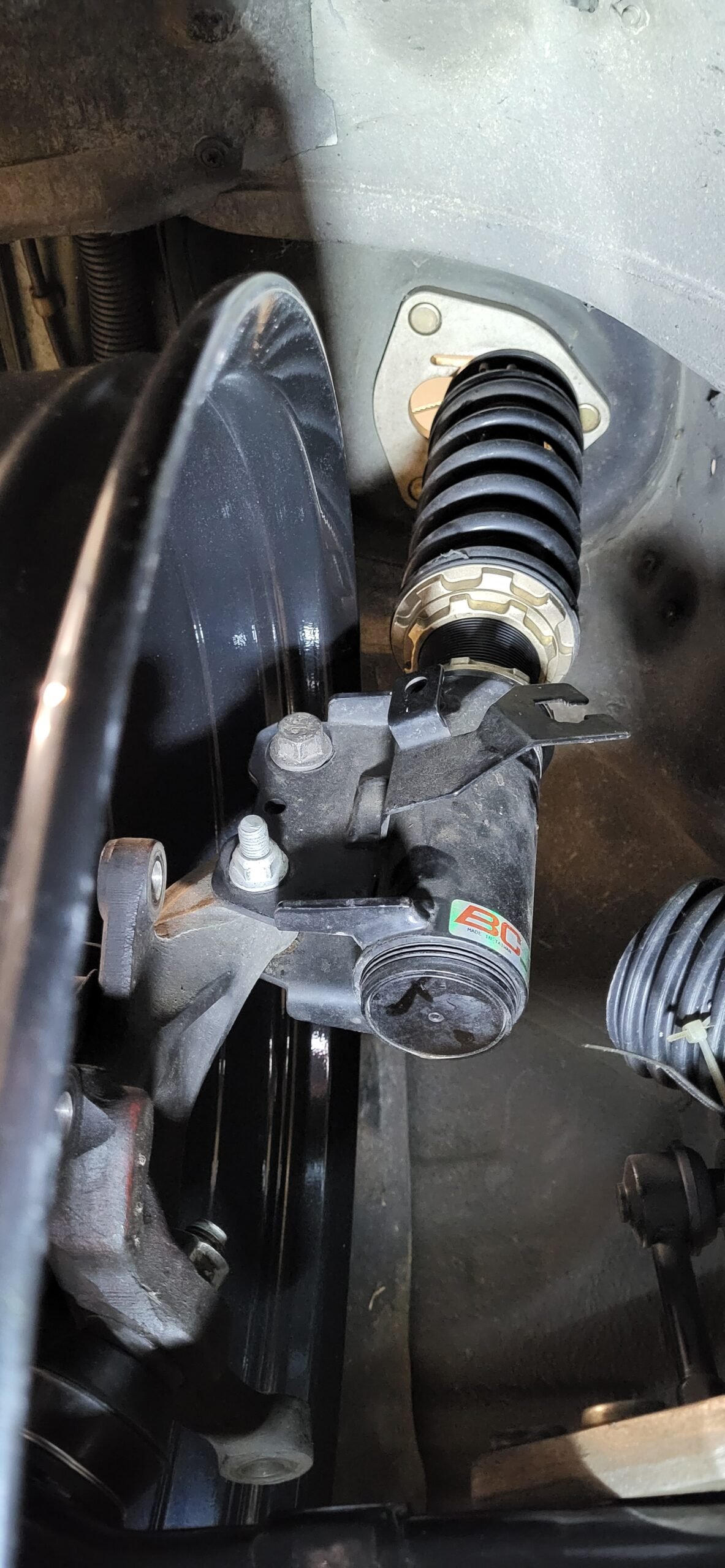

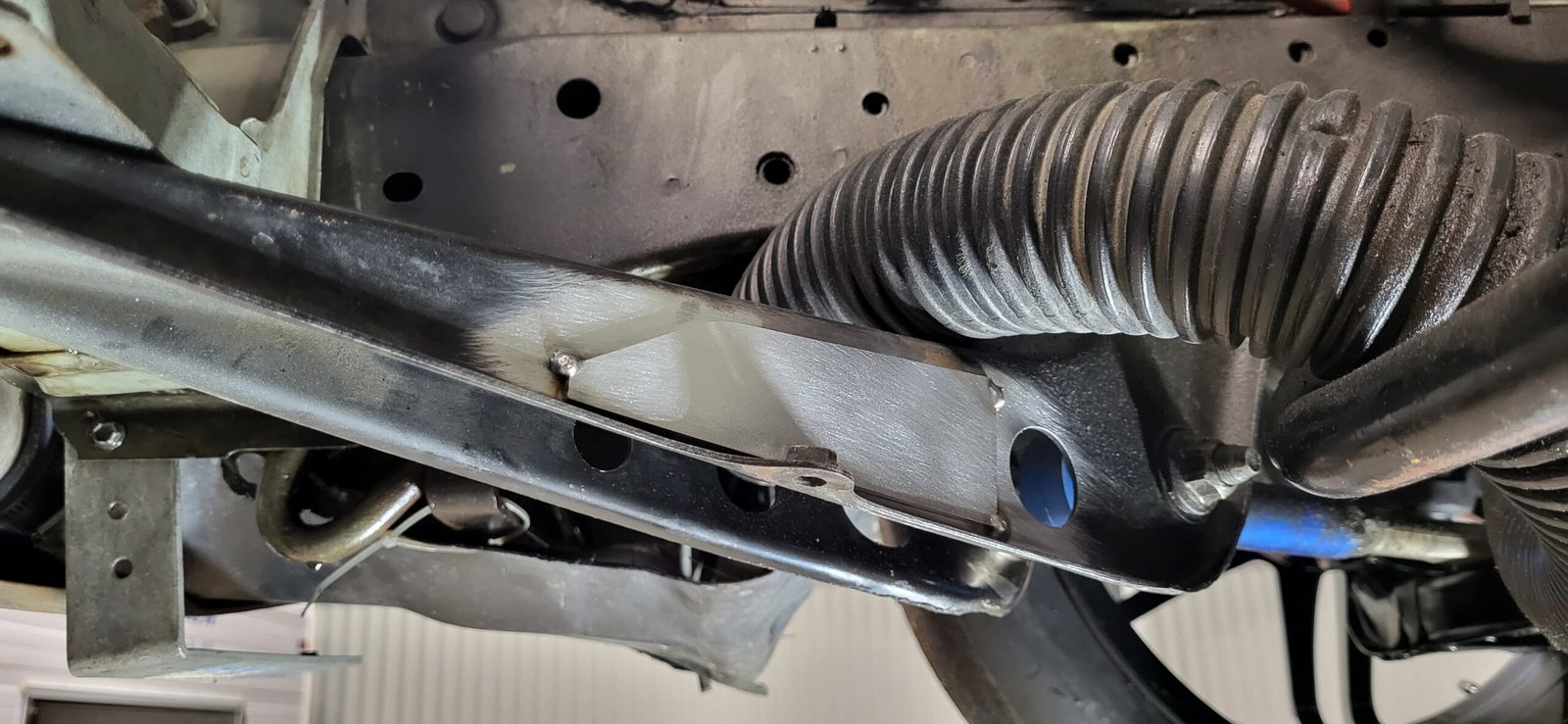

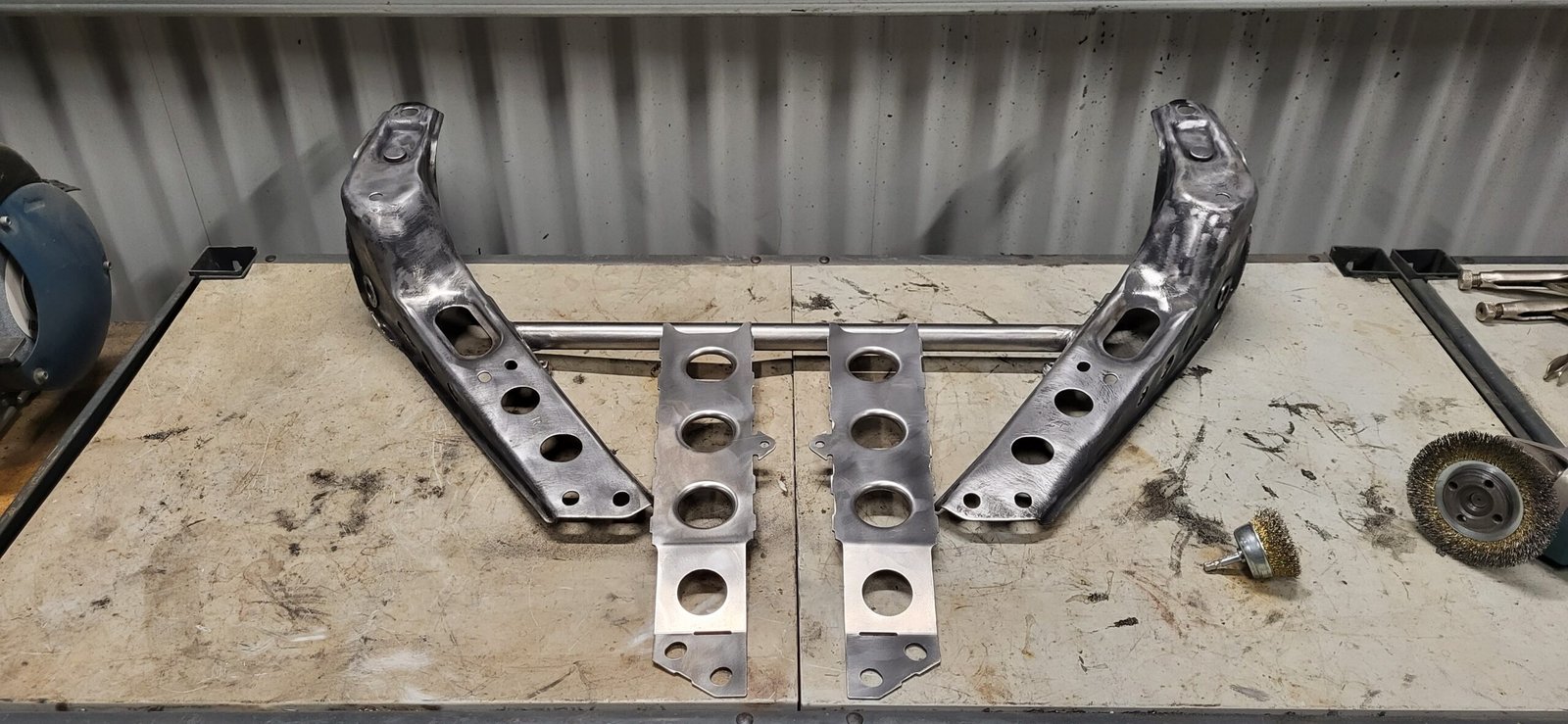

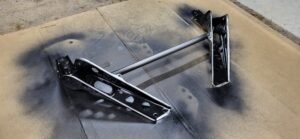

The 18×10 shows me I will need extended LCAs to get the desired camber and maintain shock clearance, so an extension kit is ordered from RB Factory and fabrication commences. Some new ball joint boots are fitted and I make the call to give the completed LCAs a lick of paint while they’re out to freshen them up.

I have a look around for some wheels without much luck and make the call to order new from Koya so I can get a 0 offset square setup – hopefully this means I can avoid spacers later. After getting some of my own Porsche slicks and getting them onto the rims, the test fit goes well but it’s obvious I’ll need wider flares and tubs to make it all work properly.

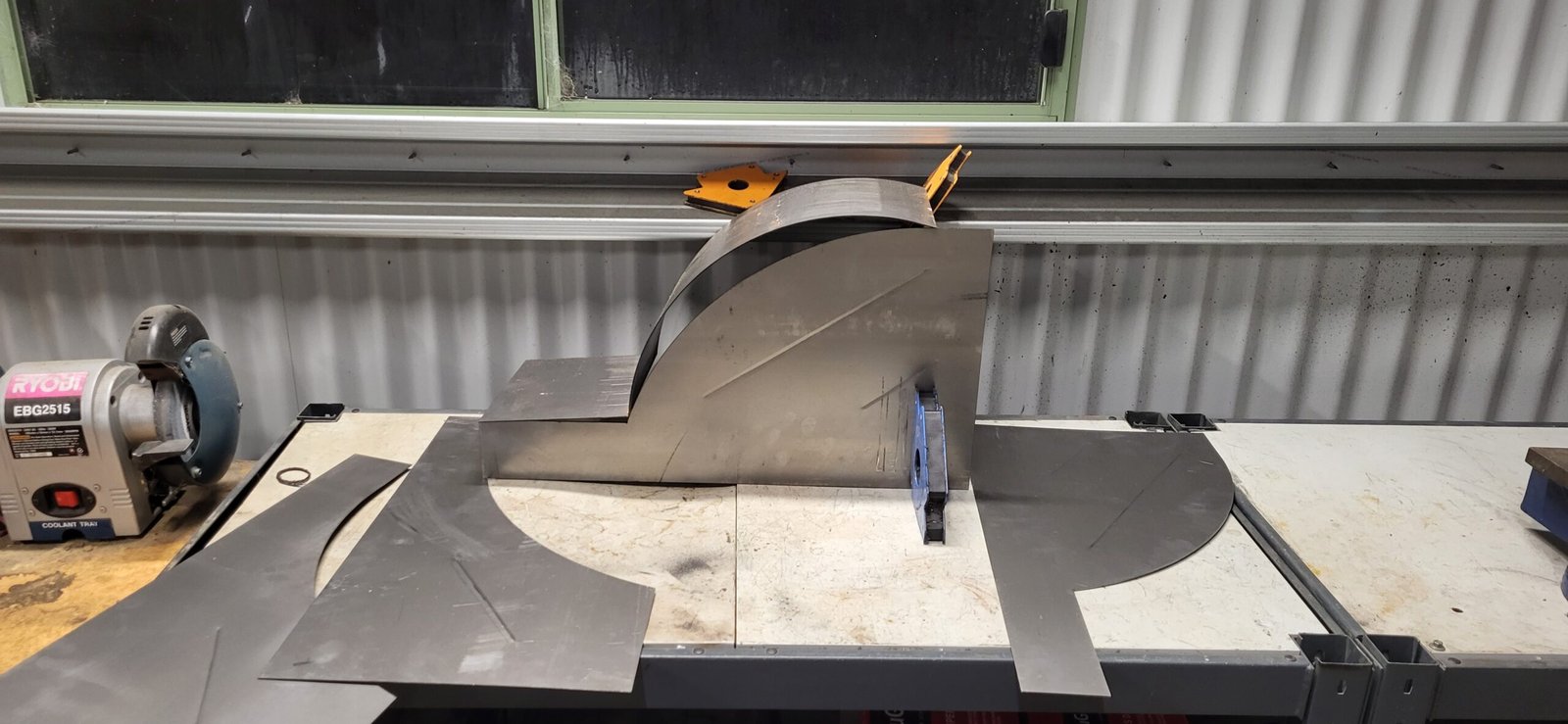

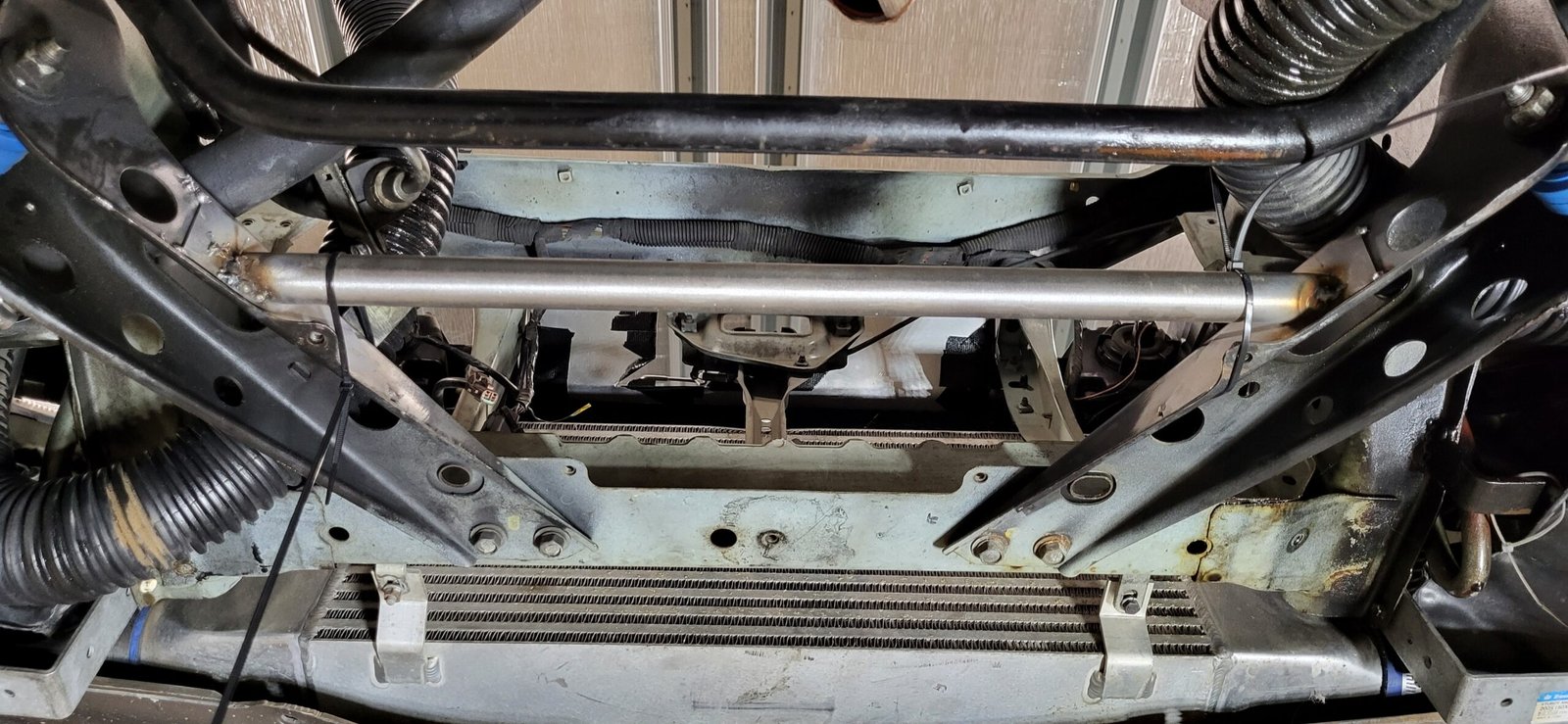

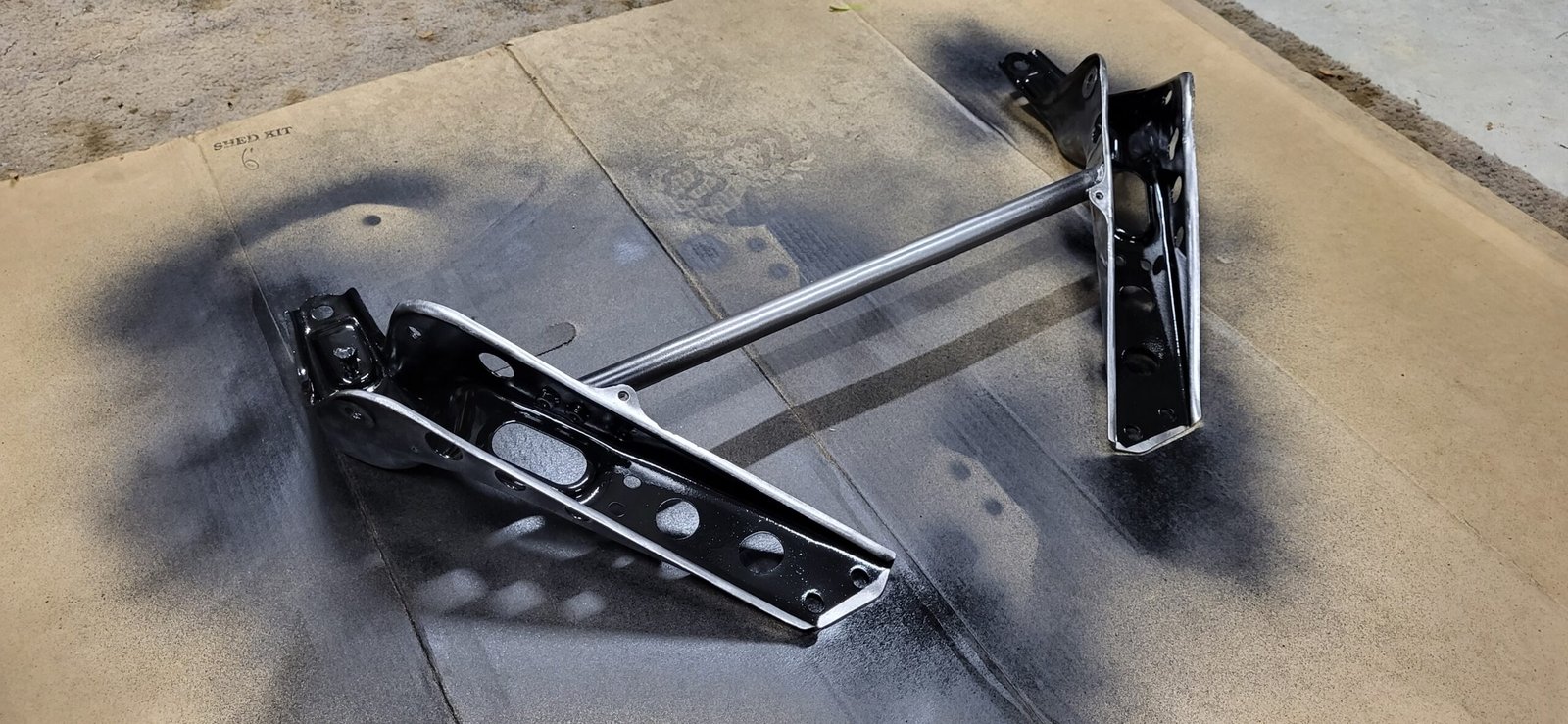

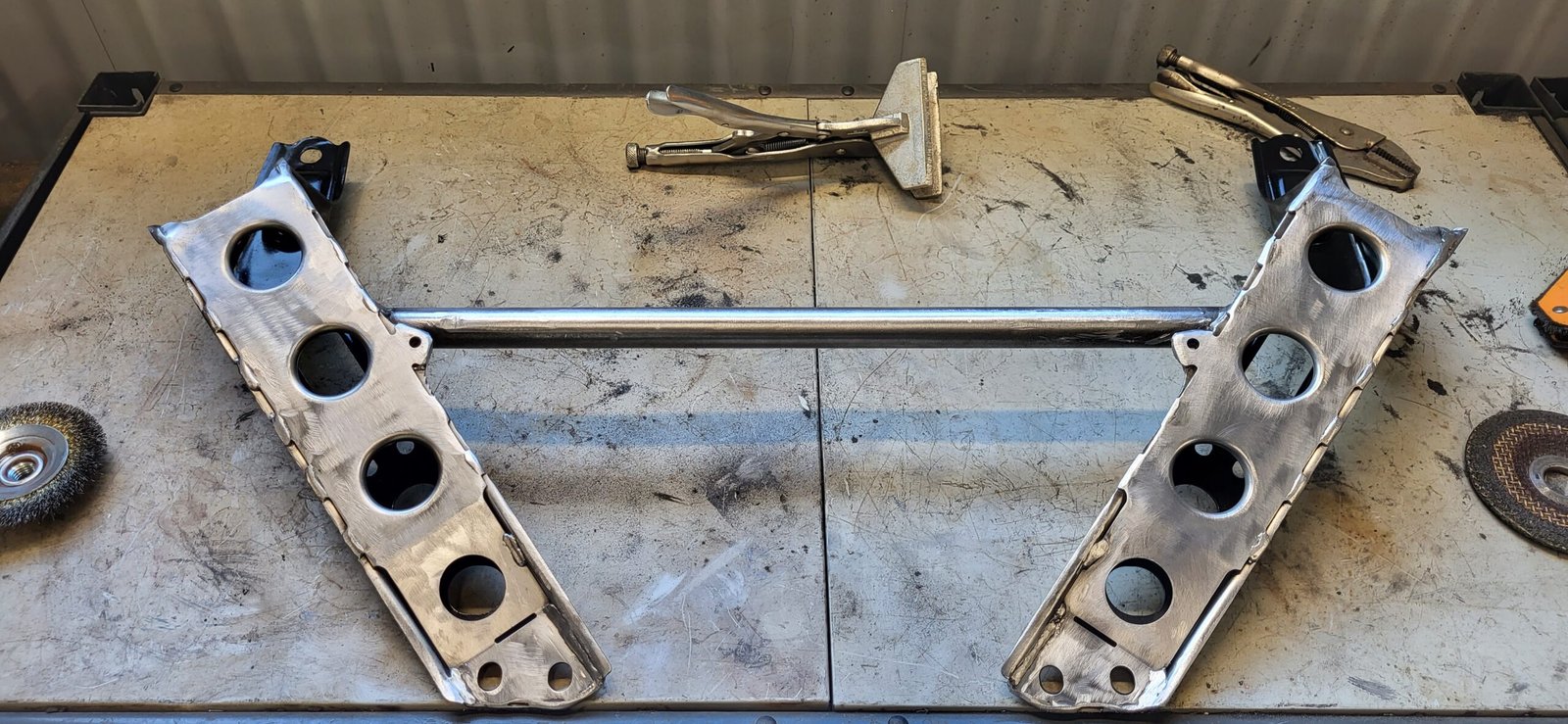

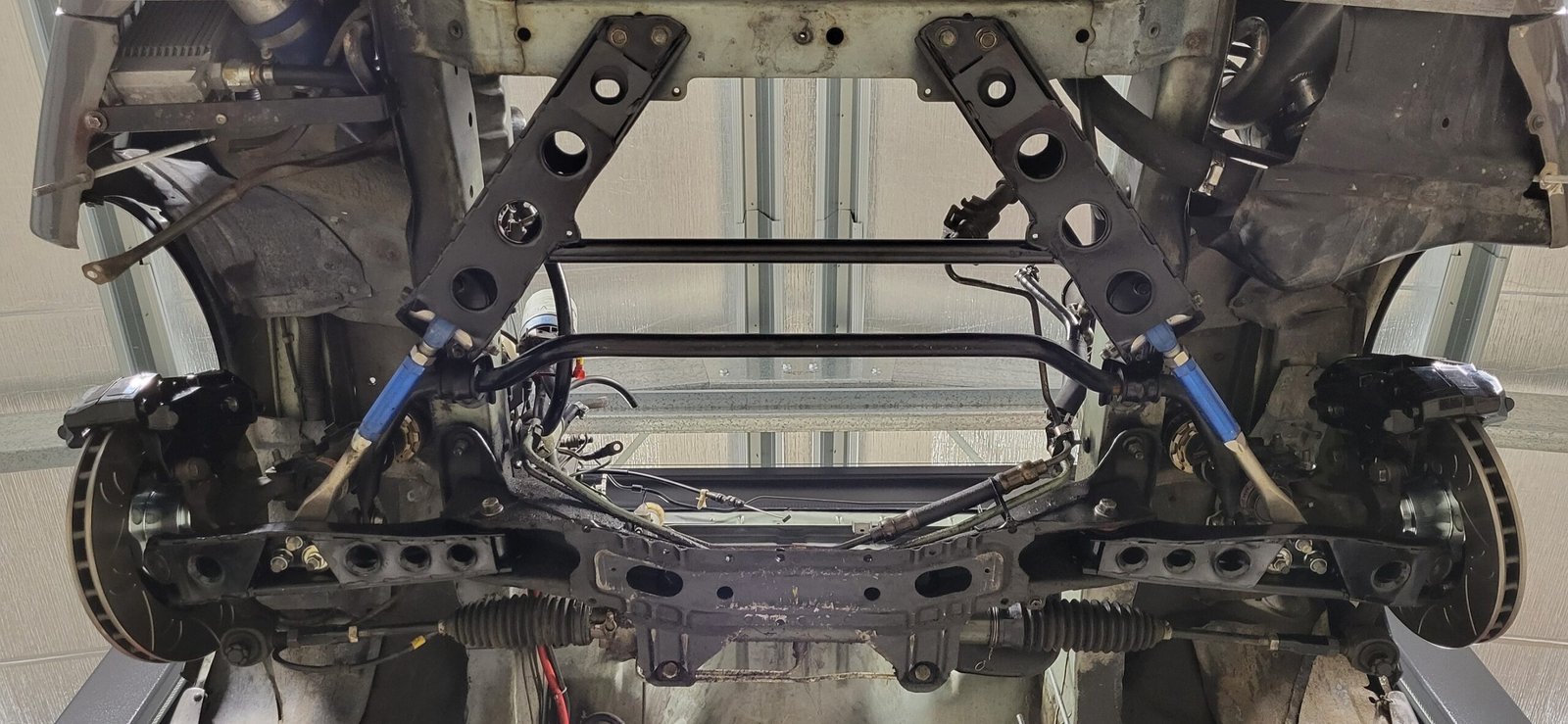

A tub kit from is ordered ATP along with a power brace and some castor brackets from GKtech and I get to work on those. With more fab projects coming I look around for an old steel bench to spruce up to make these sorts of projects a bit easier and start cleaning that up as well.

The power brake/castor bracket combo is knocked over quickly enough and I realise that I’ll need to drill the front caliper bracket holes out to M14 so that’s completed carefully and tested all OK – I ditch the remnants of the old dust shields in the process.

I’ve fully admitted by this stage this the quick refresh has gotten a little out of hand, which is fine, project creep is a real thing and I want to build a quick reliable car and that takes time and money. What I didn’t realise, is just how not quick this refresh is likely to be and the problems that lay ahead…